Our patented process innovations unlock efficiencies throughout the process, drastically reducing production time, cost and environmental footprint.

Revolutionizing Cathode Production

GHG Emissions

Our process reduces greenhouse gas emissions by up to 60% for NMC and up to 50% for LFP cathodes.

Waste Streams

Our M2CAM technology eliminates 100% of wasteful sulfate by-products.

Water Usage

We use approximately 80% less water in our production process.

Energy Consumption

Our streamlined One-Pot production unlocks efficiencies through-out the manufacturing process.

Nano One’s Innovative Process Solutions

Sulfate-Free Inputs

Our M2CAM® Technology enables sulfate-free metal powder inputs which eliminates 100% of wasteful sodium sulfate by-products while simplifying manufacturing. This innovation also unlocks flexible supply chains for increased security and resiliency.

Streamlined One-Pot Process

Central to our cathode manufacturing solutions, the One-Pot process simplifies production and enables our M2CAM® technology. Our production methods require less water and consume less energy, reducing operational cost and time while using sustainable, scalable design.

Next-Gen Durable Cathodes

Our simplified One-Pot process enables cathodes to form simultaneously with their protective coating at the nano level. This eliminates process steps and protects cathodes from degradation, enhancing durability for a longer-lasting lithium-ion battery.

Compare production processes

Standard production process

Energy intense, long, wasteful

The current processes for refining critical minerals and producing battery materials were not designed to meet the significant demands of replacing fossil fuels.

Standard production process

sulfate-based metals

Nano One’s One-Pot process

sulfate-free metals

Standard production process

energy intense long process

Nano One’s One-Pot process

One-Pot process

Standard production process

standard cycle-limited cathodes

Nano One’s One-Pot process

next-gen durable cathodes

Nano One’s One-Pot process

Streamlining the process

Our patented process innovations unlock efficiencies through-out the process, drastically reducing production time, costs and environmental footprint.

Solving tomorrow’s problems, today.

Incumbent processes are energy-intensive and wasteful. When scaled to meet global demand, it becomes untenable.

Nations differ in their environmental requirements. New supply chains will require higher standards, and if they are not done right, projects will be stalled as they secure permits.

We must address transportation costs and the emissions created along with wasted time.

The complex global supply chain is sensitive to disruptions caused by political, economic or natural events.

Currently, the recycling infrastructure for cathode materials remains underdeveloped.

Empowering The World

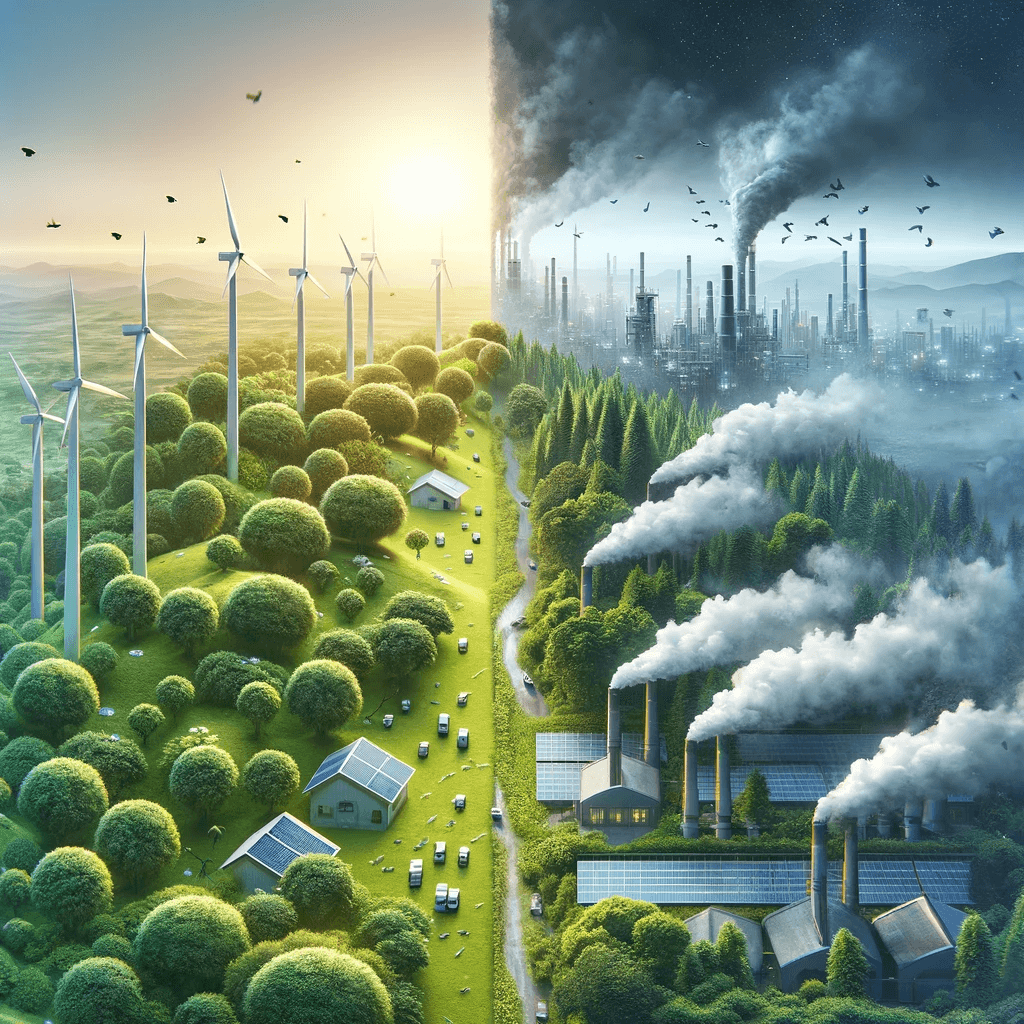

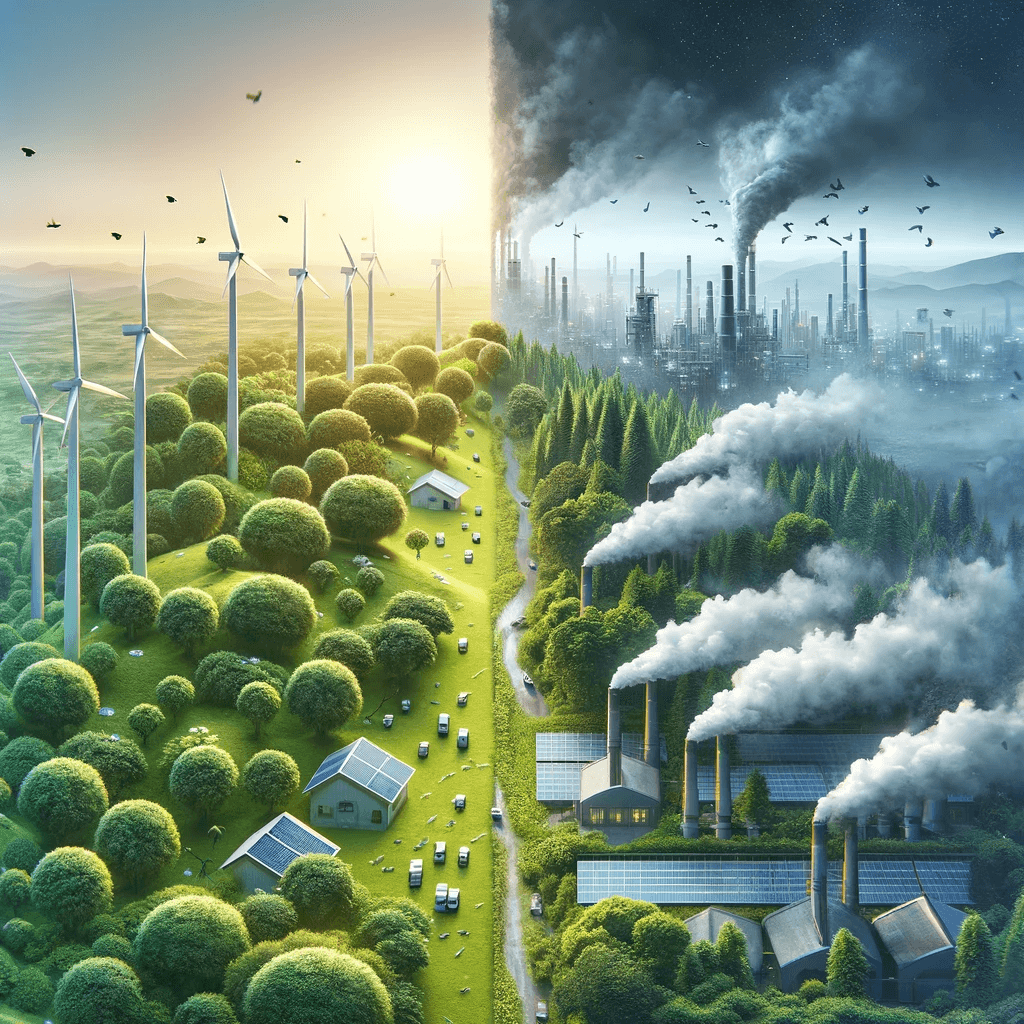

Achieving Net-Zero Target by 2050

75% of global greenhouse gas emissions are from the energy industry. This sector is crucial in preventing the most severe consequences of climate change.

Transitioning to Renewable Energy

Energy is central to both the climate crisis and its resolution. Renewable energy sources emit minimal greenhouse gases and pollutants, offering a cleaner alternative.

Increasing Electric Vehicles Adoption

We have a once-in-a-generation opportunity to change what fuels our global population of 8 billion. Essential to this shift is building supply chains with sustainable production practices.