Nano One & Worley

A detailed discussion on the strategic partnership, technology, plans, and potential for the future of sustainable battery materials production.

Transcript

00:00:05:17 - 00:00:34:07 Sebastien Dakin: So we're here today in the beautiful city of Pickering, Ontario, at the Chemetics manufacturing site to inaugurate the expansion of the plant. Sitting with me today are Laura Leonard, Group President of Technology Solutions at Worley, and Dan Blondal, CEO and founder of Nano One. The two companies announced an alliance earlier this month to globally deploy Nano One’s patented technology for the production of cleaner and more competitive cathode active materials.

00:00:34:09 - 00:00:42:17 Sebastien Dakin: So, Laura, can you first give me an overview of Worley and the plant here, and what's happening today?

00:00:42:19 - 00:01:08:03 Laura Leonard: Absolutely. Worley is a global engineering, procurement, and construction company. This means we deliver capital projects for customers worldwide in the sectors of energy, chemicals, and resources. What I do is lead our Technology Solutions business, which is a process technology division within Worley, consisting of Comprimo and Chemetics today.

00:01:08:05 - 00:01:31:01 Laura Leonard: Comprimo delivers technology for sulfur recovery, and Chemetics—the facility we are in today—provides sulfuric acid technology and chlorine chemical technology. Both of these chemistries involve highly corrosive services, which is why we have the metallurgy expertise in the fabrication shop that we are celebrating today.

00:01:31:03 - 00:01:39:15 Sebastien Dakin: Alright, thanks. And Dan, can you give me an overview of the technology, specifically the Nano One One-Pot process?

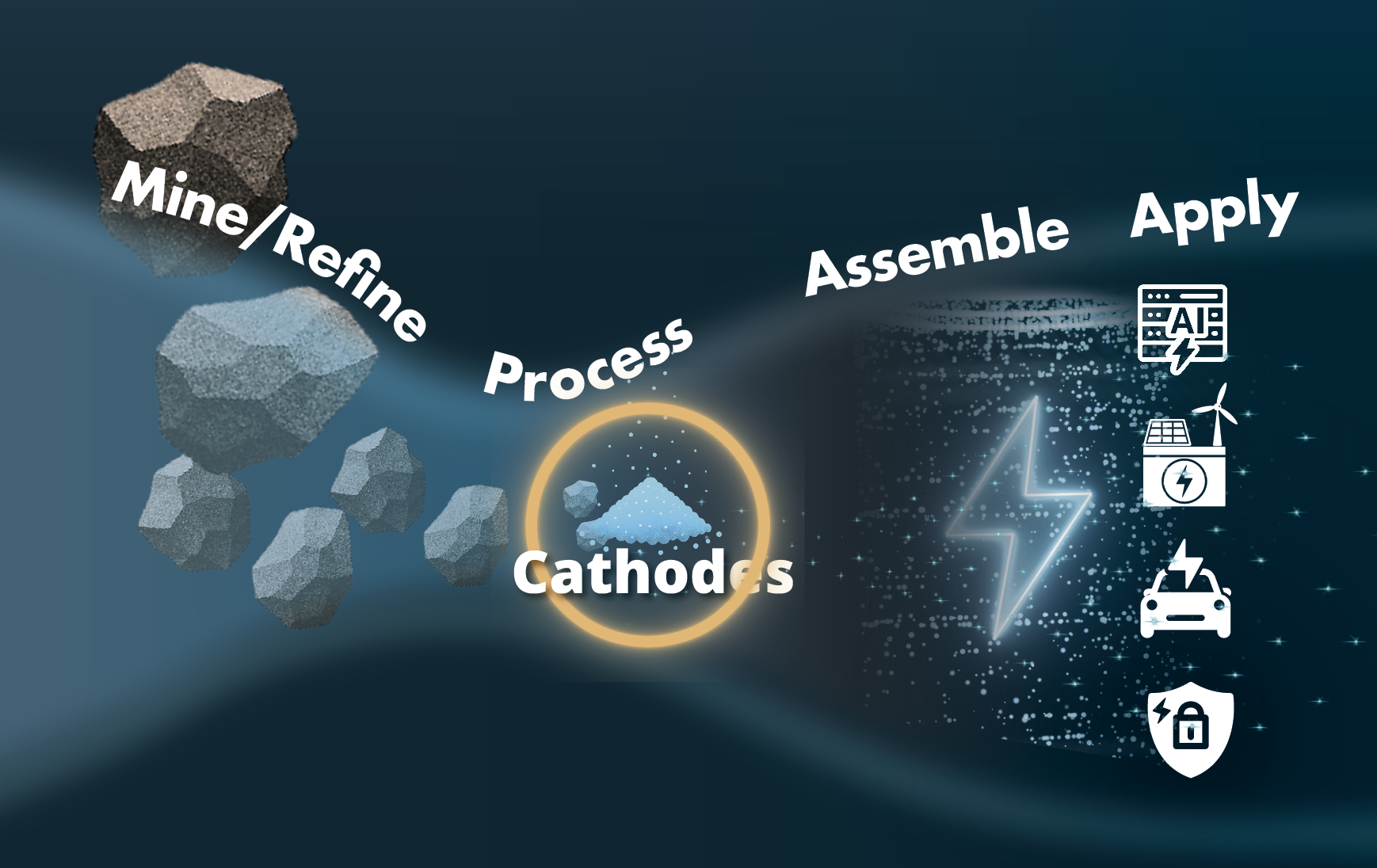

00:01:39:17 - 00:02:05:18 Dan Blondal: Sure. Our One-Pot process is a method for making cathode active materials used in lithium-ion batteries. To give everyone a sense of what that is, we combine lithium, nickel, manganese, cobalt, or lithium iron phosphate and other metals into a composite material that stores energy. This functional material goes into a lithium-ion battery, storing and delivering energy as you charge and discharge the battery.

00:02:05:20 - 00:02:31:12 Dan Blondal: Our One-Pot process integrates several industry processes into one, reducing cost and complexity while also lowering water usage, energy intensity, and greenhouse gas emissions. We completely eliminate the need for intermediate chemicals that end up in waste streams, such as sulfates and other byproducts. By doing so, we can diversify supply chains and enhance energy security for the battery industry worldwide.

00:02:31:14 - 00:02:44:10 Dan Blondal: Our motto is "changing how the world makes battery materials." This change is crucial because as we look towards achieving net zero by 2050, people have calculated that we'll need 300 terawatt-hours of installed batteries across various applications, whether in vehicles or for storing energy from wind and solar.

00:02:44:12 - 00:02:54:14 Dan Blondal: To produce 300 terawatt-hours of batteries, we would need approximately half a billion tons of cathode active materials. Achieving this scale would generate between one billion and two billion tons of sodium sulfate waste, which is unsustainable.

00:02:54:15 - 00:03:18:14 Dan Blondal: We are still in the early stages of this industry. To reach these volumes, we need to solve scalability issues. That's what we're focusing on: solving the problems that allow us to deliver the batteries and supply chains needed to meet demand sustainably, as stewards of the environment.

00:03:18:16 - 00:03:41:05 Dan Blondal: So, yes, our technology is very disruptive. The current technology has evolved over the past 20 to 30 years, primarily in Asia, where the waste streams and byproducts were initially manageable. However, as these processes have scaled, the problems have grown significantly. Exporting these processes to the West or other regions without addressing the large-scale environmental issues is challenging.

00:03:41:10 - 00:03:59:17 Dan Blondal: We aim to disrupt this by still utilizing nickel, iron, and lithium, but sourcing these materials in a way that avoids the environmental issues I mentioned earlier. Disrupting the supply chain requires large partners like Worley to help us execute our vision.

00:04:03:09 - 00:04:24:13 Laura Leonard: Our purpose at Worley is to deliver a more sustainable world. We've identified battery materials as a key area to focus on to empower the energy transition. Our expertise in the resources and chemicals sectors positions us to support new technologies in the battery materials space.

00:04:24:19 - 00:04:52:01 Laura Leonard: Our ambitions in the battery materials and cathode industry align with recognizing the need for more battery materials globally. We've positioned ourselves to be the partner of choice for deploying technologies and executing projects efficiently.

00:05:11:16 - 00:05:32:04 Laura Leonard: We've partnered with Princeton University and identified five key shifts needed to achieve net zero by 2050. In our alliance with Nano One, we embody two of these shifts: enabling new technology options and standardization. Standardization helps reduce costs and accelerate deployment.

00:10:07:10 - 00:10:19:08 Laura Leonard: Standardizing our processes allows us to bring down costs and accelerate the deployment of new technologies. This is crucial to meeting the significant capital requirements for achieving net zero.

00:12:22:00 - 00:12:34:13 Laura Leonard: The One-Pot process offers technology that addresses environmental challenges, making it easier to deploy in North America and Europe, where older technologies face hurdles.

00:14:00:14 - 00:14:49:00 Dan Blondal: The next steps involve combining our know-how into early-stage process engineering design packages. These packages will be marketed to our combined networks, defining the plant designs for global deployment. This process will take months, but we expect significant progress in that timeline.

00:14:52:04 - 00:15:15:21 Laura Leonard: The next 6 to 12 months will focus on finalizing the standard design and engaging with potential customers to deploy the One-Pot process quickly. We're already seeing positive inquiries and synergies in our relationships.

00:15:39:07 - 00:16:00:11 Dan Blondal: This partnership accelerates financial decisions and reduces risks for project lenders and large companies. Having everything done upfront is crucial for wide-scale adoption of the technology.

00:16:00:12 - 00:16:08:06 Laura Leonard: We hope that next time we sit down together, we will have a customer at the table, discussing our technology deployment.

00:16:08:07 - 00:17:16:08 Dan Blondal: The goal is to see significant growth in locally produced cathode materials with diversified supply chains. We expect this to take off as demand builds, not just in Canada but globally.

00:17:16:10 - 00:17:47:17 Laura Leonard: We're well-positioned to change the world by delivering a more sustainable future together.

00:17:47:19 - 00:17:48:14 Sebastien Dakin: This is the beginning of a great story for both companies and the battery industry. Congratulations to both on the alliance and to Worley for the plant expansion. I wish you both resounding success in the near and long-term future.

Dan Blondal: Thank you.

Laura Leonard: Thank you.

About Worley

Worley is a global professional services company of energy, chemicals and resources experts. We partner with customers to deliver projects and create value over the life of their assets. We bridge two worlds, moving towards more sustainable energy sources while helping to provide the energy, chemicals and resources needed now. Worley Limited is headquartered in Australia and listed on the Australian Securities Exchange (ASX: WOR).

Disclaimer

Certain information contained herein may constitute "forward-looking information" or a "forward-looking statement" within the meaning of Canadian securities laws. In general, forward-looking information is presented by the use of terms such as "believe", "expect", "anticipate", "plan", "intend", "continue", "estimate", “can”, “will”, “should”, “ongoing”, “target”, “goal”, “accommodate”, “build”, “commit”, “potential” or variations of these words, phrases or statements that certain events, actions or results may or will "happen." Forward-looking statements based on the current opinions and estimates of management as of the date such statements are made are not, and cannot be, guarantees of future results or events.

Forward-looking statements are subject to known and unknown risks, uncertainties and other factors that may cause the actual results, level of activity, performance or achievements of Nano One Materials Corp. (“Nano One”) to be different from what that is expressed or implied by such forward-looking statements or forward-looking information. There can be no assurance that such statements will prove to be accurate, as actual results and future events could differ from those anticipated in such statements.

Accordingly, viewers should not place undue reliance on forward-looking statements and information. Nano One disclaims any intention or obligation to update any of the forward-looking statements or information incorporated herein by reference, except as required by applicable securities laws. This video is not a solicitation to buy securities and does not constitute an offering document under securities laws. None of the information or analyses presented are intended to form the basis for any investment decision, and no specific recommendations are intended. Viewers are encouraged to review additional risk factors as identified in Nano One’s MD&A and its Annual Information Form dated March 27, 2024, both for the year ended December 31, 2023, as well as Nano One’s regulatory filings on SEDAR+ at www.sedarplus.ca.